- #Raspberry pi vs arduino for nixie tube block install#

- #Raspberry pi vs arduino for nixie tube block update#

- #Raspberry pi vs arduino for nixie tube block full#

- #Raspberry pi vs arduino for nixie tube block code#

(There's also a nixie gearshifter with the nixie tube embedded in the handle in the mix, but that needs no coding or programming since it operates on a set of microswitches)

#Raspberry pi vs arduino for nixie tube block full#

The oil pressure bar will flash at full scale when the oil pressure warning is on. The battery level bar will flash at full scale when the charge warning light from the alternator is on The tachometer bar will be set so that full scale is the optimum gear shift point, with some overhead to send it bright (since bars just get brighter when you try to drive them further than full scale) so it would act as a handy shift light (possibility to set the shift point manually - but I'll stick that in "pipe dreams" for now!) Nixie bar tachometer (to compliment the digital tachometer)Įach bar will flash at whatever value it is currently reading when parameters fall below or above preset levels to alert of potential issues (such as boost creep, temperatures getting a shade high etc)Įach bar will flash at full scale when there is no input signal at all (that is, a zero input) A nixie dashboard is the goal, featuring: Which then puts me into a new learning experience, coding from scratch!Īnd, so, on to post #2 where I will lay out what I am trying to achieve!įor those of you with an attention span similar to mine (that is, very short!) and therefore skipped the yawnfest preamble, welcome to the problem I am trying to solve! You didn't miss much.įor those who read the preamble, well done, and thank you! But, becuase i have "proved" I can do it with circuitry, and had that learning experience and done it in principle, I am going to "allow" a shortcut here (and a saving of several hundred pounds!) by using an Arduino to do the job in "one hit". Then I realised that the effort, and cost, would not be worthwhile. So then I started to re-design to only use through-hole components rather than their more modern surface-mount counterparts. Then I got some quotes to have the board made. I drew up a board to run the dashboard (that's a lie, I was drawing up a board and then stumbled upon someone who had the same idea as me, and had already finished a board to run a nixie tacho, and had made it open source and published the design so I lifted that, tweaked it, altered some parts and added to it the rest of the circuits to run the rest of the dash). I want to use nixie tubes for the dash.Īnd a whole bunch of bars for various other parameters. So far, this has been a steep learning curve (with problems such as oil flowing into the intake when the throttle shut off owed to a change in turbocharger manufacturing techniques), but a well worth-it exercise to re-learn some lost knowledge and techniques. The project had a stric rule, that I was only allowed to use period technology available at the time of manufacture.

She is currently in bits, going through a major body-off chassis resto and a few modifications (most Well, thought I would stick a couple of pics up of my roof chopped turbocharged Volksrod.

Bad Juju the roof chopped turbocharged Volksrod.

#Raspberry pi vs arduino for nixie tube block update#

I won't put it all here, but there is a thread (which I no longer update for reasons best left) just here that you can flick through if welding, turbochargers, crazy customisations, obscene amounts of hard work and old beaten up Volkwagens are your thing. I am building a hotrod, which has so far had absolutely enourmous amounts of work go into the body, chassis, engine. I suppose I had better start with an introduction of what it is.

#Raspberry pi vs arduino for nixie tube block code#

This is my first time "properly" trying to code from scratch.

#Raspberry pi vs arduino for nixie tube block install#

Sadly, this has meant that I have been left with a broad understanding of what a code "does" but not "how", much in the same way someone can install a washing machine in a house or an engine in a car using a manual or instruction book, and not have the foggiest idea how it actually works. I've "programmed" 3D printers but that was largely "cheating" using tools like the Repetier configuration tool.

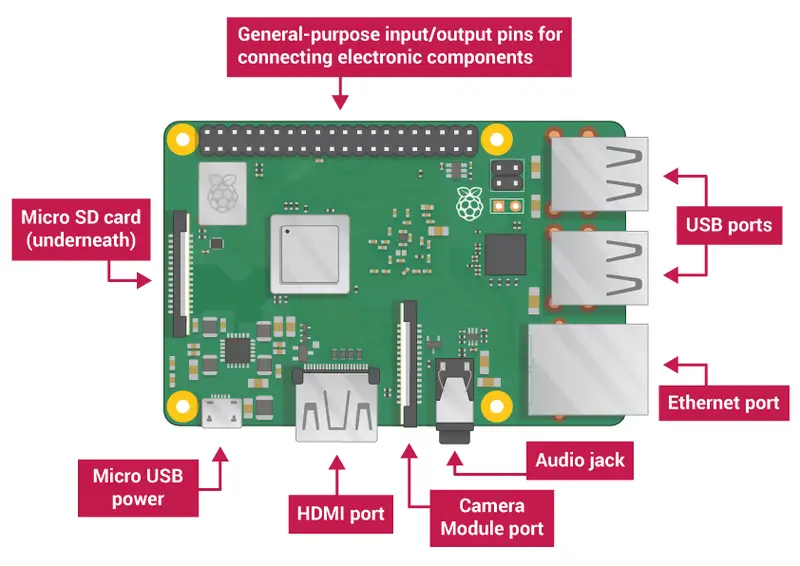

Either that, or using useful code builder tools for the likes of Libelium motes and such. I am not "new" to arduino (and raspberry pi etc) but most of what I have done before is lifting a code, tweaking it, maybe bashing two scripts together, compiling and off I go. for those with some time to kill, read on!

for those with a short attention span, or who don't like preambles, skip to post number two which will explain what I am trying to achieve. Firstly, thank you to all the contributors on this forum, I've found some fantastic advice already.

0 kommentar(er)

0 kommentar(er)